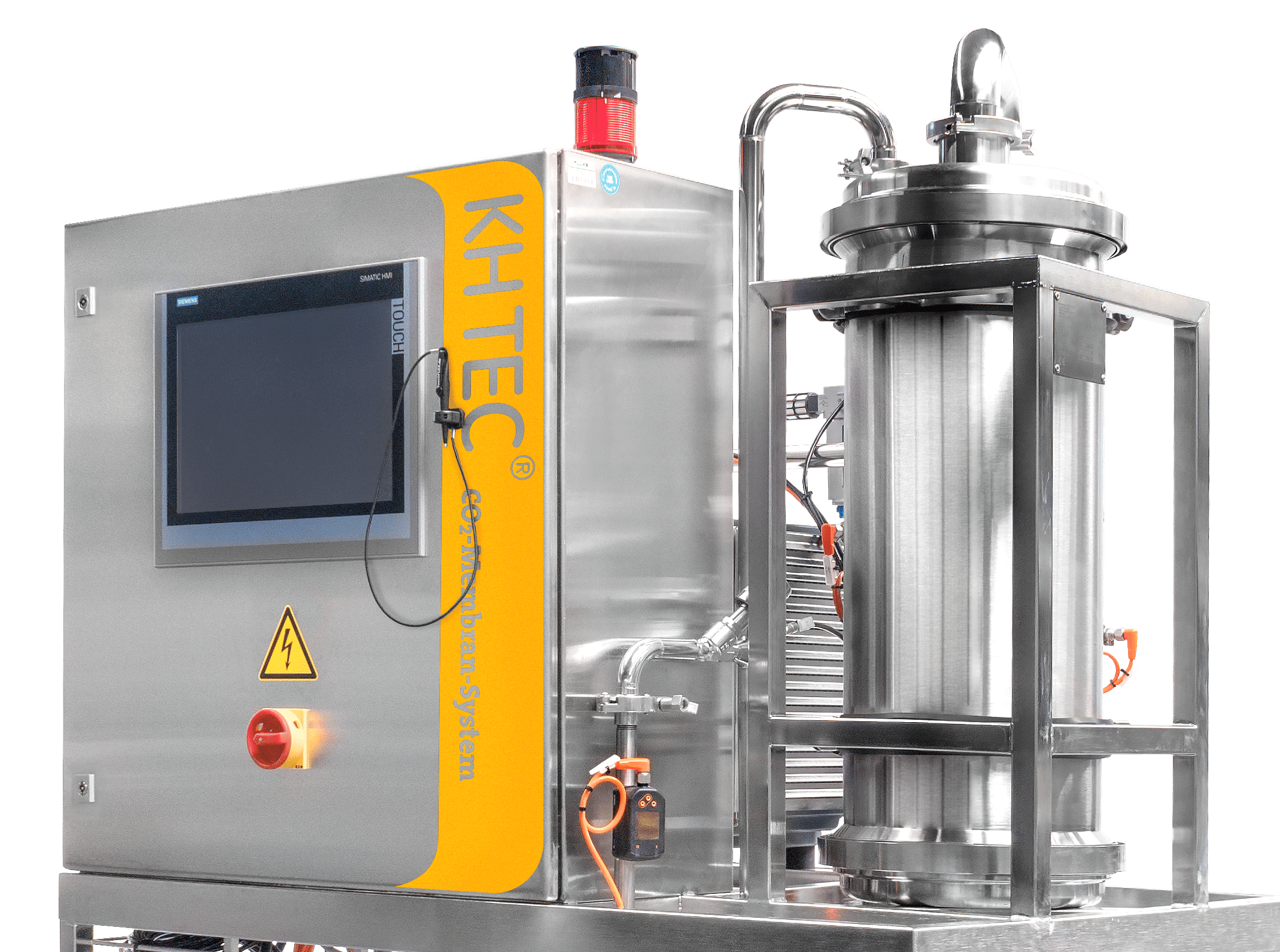

About the KH Tec CO2 Membrane System

VAF Memstar are agents of KH Tec in Australia and New Zealand. The KH Tec Gas Membrane System is a cutting-edge solution for precision-tuned CO2 adjustment and efficient O2 removal in beverages. The system can increase, decrease, or maintain CO2 levels, while also efficiently eliminating Dissolved Oxygen (DO) from beverages during the same process. This capability offers precision and flexibility in delivering beverages tailored to your specifications.

The KH Tec CO2 Membrane System is designed as a continuous, single-pass system, a feature that lends itself to effortless integration with other systems for streamlined, end-to-end beverage processing.

Experience the superiority of the CO2 Membrane System in the drastic reduction of lead times for carbonation and degassing processes. It simplifies and enhances efficiency through fewer process steps compared to conventional methods, and with its continuous operation capability, the KH Tec CO2 Membrane System can be seamlessly connected in-line to your bottling line, further enhancing workflow efficiency.

How does the KH Tec CO2 Membrane System work?

The effectiveness of the KH Tec CO2 Membrane System originates from its state-of-the-art hydrophobic membrane technology. In this process, the beverage is channelled through a specialised membrane designed to facilitate the exchange of gases, while preserving the beverage’s essential components. This ingenious procedure results in the creation of ultra-fine CO2 bubbles, enhancing the beverage with a superior, delicate mouthfeel.

The system’s high degree of automation is driven by numerous process sensors and actuated valves, guaranteeing precision operation. With the KH Tec CO2 Membrane System, customising the CO2 concentration in beverages is effortless, and is adjustable anywhere from 0 to 9 g/L (with an extension capacity of up to 12 g/L).

We offer a range of KH Tec CO2 Membrane System models tailored to meet unique operational requirements.

Benefits of KH Tec

- Efficient and cost-effective.

- Capability to directly connect to your bottling line.

- Accelerated filling speeds due to reduced foaming.

- Consistently accurate and repeatable performance.

- Foam-free gassing.

- Foam-free CO2 removal.

- Production of ultra-fine bubbles in carbonated products.

- Wide-ranging flow rates from 5,000 – 45,000 litres per hour *.

*Customisation options are available to meet unique customer requirements.

Equipment

KH Tec CO2 Membrane System

A cutting-edge solution for precision-tuned CO2 adjustment and efficient O2 removal in beverages

EnquireContact Us

Contact VAF Memstar today about our diverse range of filtration and processing services, available in a diverse range of capacities and mobilities.