Volatile Acidity Reduction

VAF

Managing volatile acidity (in the form of acetic acid & ethyl acetate) in wine production is crucial as excessive levels can lead to unpleasant characteristics in a finished product. In the same manner, volatile imbalances can radically alter a wine’s aroma, balance and ultimately, market appeal. Our unique VA reduction service can accurately reduce volatile acids efficiently and safely – providing cost-effective solutions while maintaining quality.

How do we reduce volatile acids?

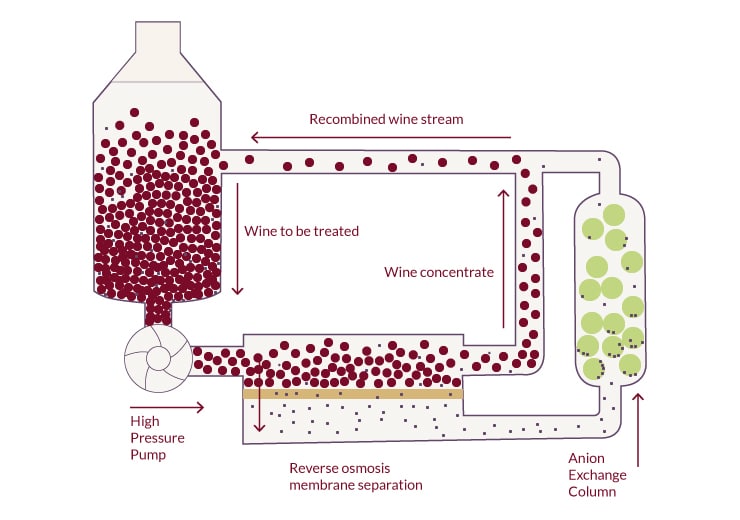

The VA reduction process involves circulating the wine through a reverse osmosis plant to isolate a permeate to be treated. This permeate – comprised of water, alcohol, and the volatile acids to be corrected – is treated in an anion exchange column that absorbs the acetic acid. Finally, this treated solution is recombined with the concentrate and returned to the tank.

Benefits of VAF

- Significant impact upon stuck fermentations

- 30% minimum volatile acid reduction on a single pass

- Efficient 1,800 – 4,000 litres per hour

- Capable with small or large-volume processing

- Selective membranes capture only volatile acid, preserving quality

- Lower treatment pressure places less stress on the wine

Downloads

Equipment

Contact Us

Contact VAF Memstar today about our diverse range of filtration and processing services, available in a diverse range of capacities and mobilities.